squisher

THE CALM ONE!!!!

Road a basket on a crane this morning. Deadwooding and taking some limbs/dead tops out of some big nasty old cottonwoods. It was a fun half day.

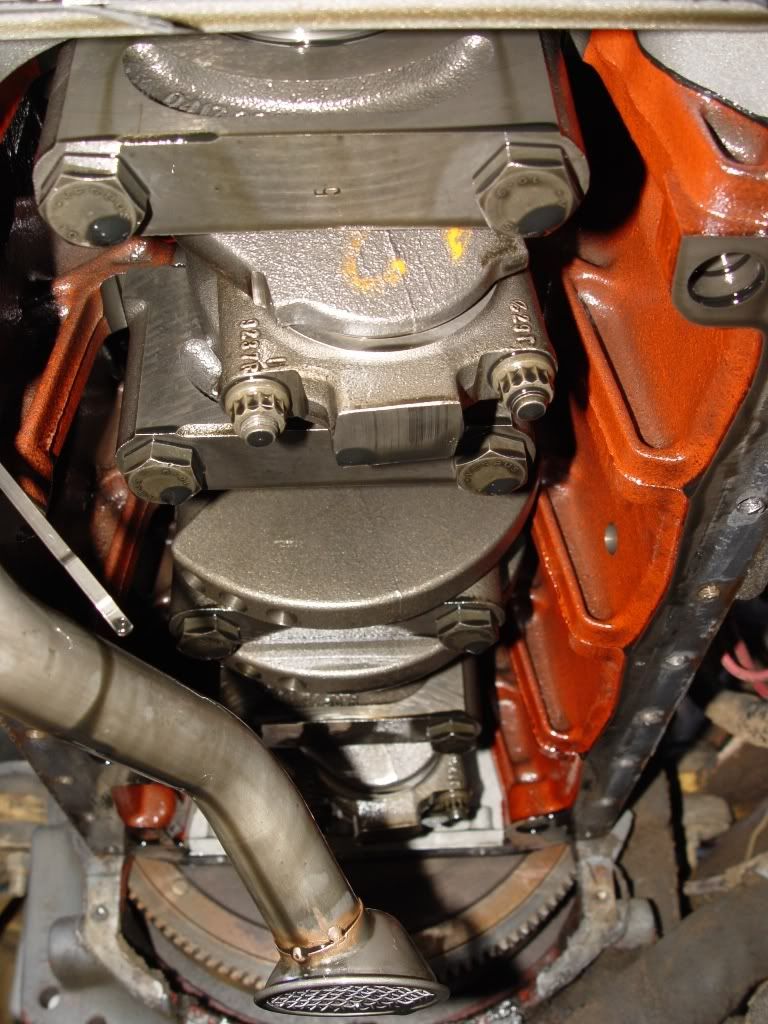

The top of the lifter is still in the engine.

The top of the lifter is still in the engine.

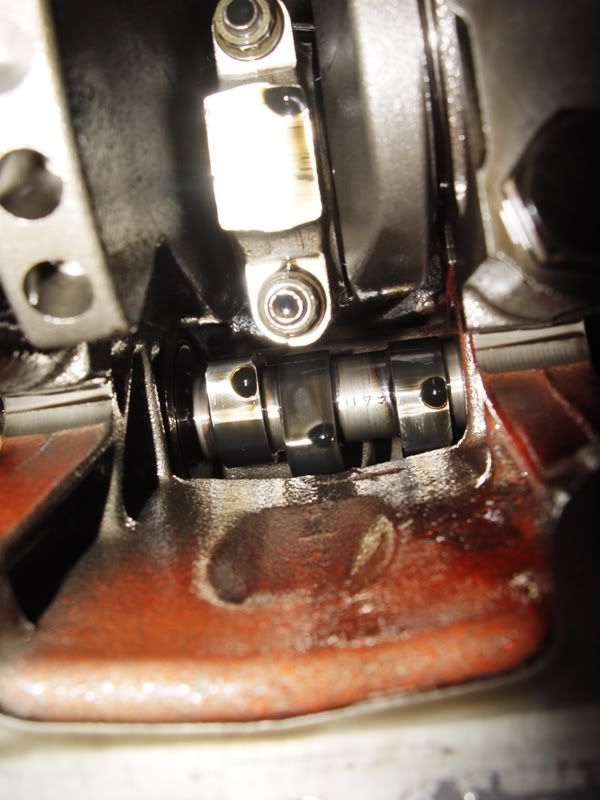

I asked about a price for a camshaft, just to give me something to think about while I was pulling the pan. Turns out there isn't a spare shaft in the US, so it'd take 3-5 days to get one here from Germany, i can only imagine what that'd cost. Luckily my cam is fine, although the shot of the intake lobe below looks scuffed, it isn't best I can tell. I'll have the cam out to replace the lifter.

The hypothesis I currently have is that the lifter and rocker stand both developed cracks when the piston smacked the valve the last go round.

Is it an oil cooled deutz?? if it is you might have all that metal everywhere.

If the piston hit the valve I would guess it would bend the valve before it would have cracked the rocker and lifter.

I think you might have something else going on, it seems the valvetrain problem is working its way inward.

I dunno, I could be wrong but I think your going to have problems.

) So I went by DMV ... Did not make the job site till 10:30 after they doubled my registration fees. Nuttin compared to you guys though.

) So I went by DMV ... Did not make the job site till 10:30 after they doubled my registration fees. Nuttin compared to you guys though.

...LJ I think you're going to have to disassemble and inspect the whole valve train.