i've used 3strand New England Safety Blue/hyvee(don't see listed) a bunch long ago, wore like iron, cheap, easy eye splicing(and single marked strand in splicing is helpful). Have flattened around a drum tho, but was probably really pushing (i mean pulling)it.

.

Other considerations to 3strand over braids i think i see are:

>>the more textured lock together in knots of more fitted/self bedding parts drawn up as one more so than round vs. round of braids.

>>Unique grip characteristics to that of braid, by this texture, in mating to surfaces

>>part of which is, have theory that i see better ventilated frictions(?), than the more solid 'sock' of a braid(?!). Partially from riding a whole lot of 3 strand spit tails , usually for Blake's hitch onto then a solid braid to ride as lifeline/rope column. Can use matching diameters of tail and and lifeline if only single pull on tail/cord. But would need lesser diameter of stiffer material cord, for a tail/cord pulled from both ends i think tho.

.

GRIP usually the most elusive property of rope control

>>as takes opposing rope part on other side of host

>>preferably both rope parts arc180, not linear

so seeing it a a positive sign to see it manipulated here

.

As said easy to splice, and one of my main benchmark models is a lesson from late Brion Toss.

Starts out by saying is counterintuitive, many fuss to keep rope strands round thru a whole 3strand splice, with best intentions, even yell at others to do so..

Try to keep the solid/primary side same diameter and shape for strongest splice(less deformity) with also most friction force offered(organic round shape of strands).

Then make eye, dbl. bury 1st strand,

BUT, work to 'ribbon' as the rope reeves/laces thru the primary side

>>the flat ribbon giving less disruption/deformity to the primary side

>>while also presenting more frictional area than if left to be round vs. round on the pass thrus

>>while the arc surface of the primary made gauntlets of turns that the ribbons formed to

Then his 'butane backsplice' coming out the final weave, as a flared bell that couldn't get back thru the first pass very easily..

Spliced up many round and eye2eye slings for cheap, rough usage, usually from degraded, cut done, more primary use lines when new.

i always worked to keep my primary load side of anything as 'pristine', w/o deformity as possible from this lesson ;

of what would think is about the ultimate knot strength/ long splice(less deformity over longer taper).

And several other key lessons too that have guided me.

.

Am stuck in drawing hell on item meant for the previous post and removed at last minute as just not good enough(own worse enemy).

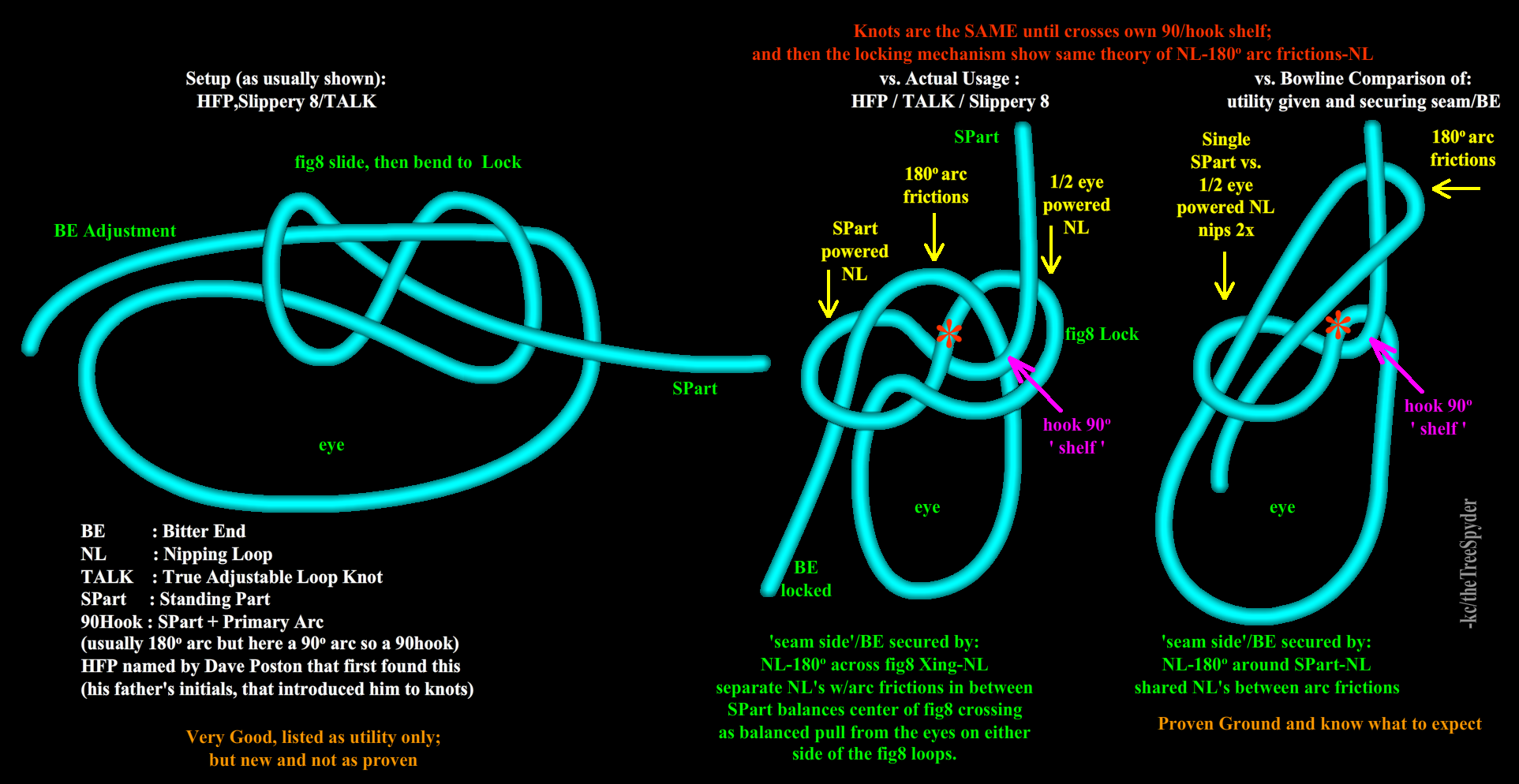

On how to easily use HFP Slippery 8 as 3x single pull tighten coming out of eye on the solid (not seam)leg,

>>then quickly set nip once drawn up tight.

Gonna have to set it aside for now i think/and clear head, but that is the idea.