lumberjack

Young man on the go

- Thread Starter Thread Starter

- #226

We'll see if I get them or not, waiting to hear from the guy, will probably be tomorrow.

At one point I thought about doing an 8x8x8, but that would be too wicked methinks. A 6x6x4 would be interesting, but still a bit too wild. Designing a suspension that would be good in the rocks/trails would be a doozy how I'm currently thinking.

At one point I thought about doing an 8x8x8, but that would be too wicked methinks. A 6x6x4 would be interesting, but still a bit too wild. Designing a suspension that would be good in the rocks/trails would be a doozy how I'm currently thinking.

) and asked how many feet of tubing he used, he said 250', more when it was finished. See below for the 2 pm's.

) and asked how many feet of tubing he used, he said 250', more when it was finished. See below for the 2 pm's.

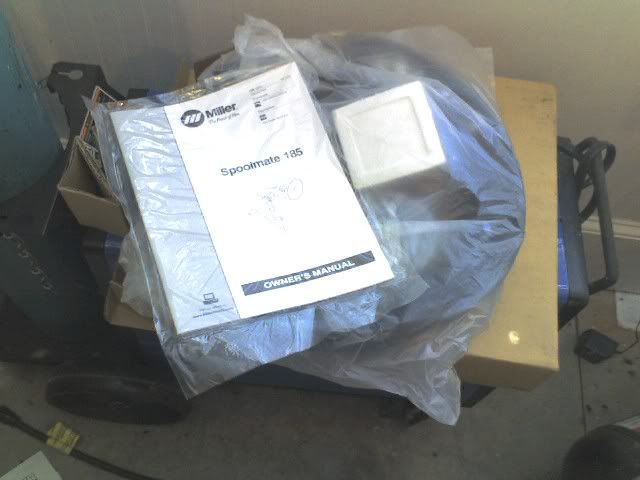

I never thought I'd need to do aluminum, but now I'm getting into it, and need to get set up with a tig eventually to do so(thin work... not plate).

I never thought I'd need to do aluminum, but now I'm getting into it, and need to get set up with a tig eventually to do so(thin work... not plate).