i guess i take their view thar bro, sorry i missed this

>>and larger pulley is easier on rope and more leverage ratio(all else held as same) over bearing/bushing etc. for higher efficiency in both departments.

.

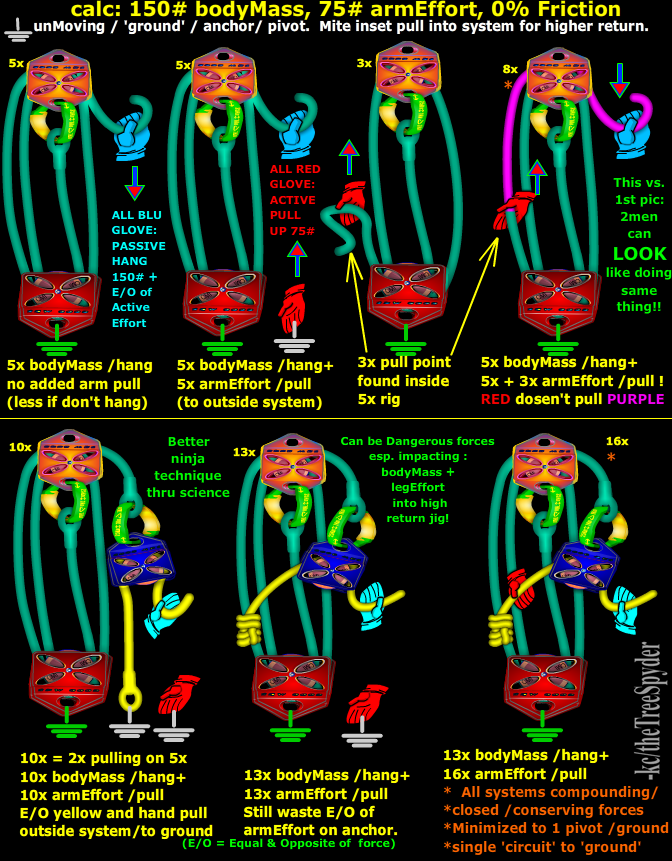

In all examples i think it is best to set parental extremes/bordering potentials, then limit to that finite

>>as a domain, then divided

>>or taxed by friction etc.; but show all math/homework as full disclosure model

>>friction is a variable of the domain, not a definition of the domain type model

.

This is all yin/yang to me

>>the full potential extreme and then it's non of Zer0 as purebred parents, points between inherit so much of each

>>just as cos1(100%)and cos0(0%)@ 90 degree crossing, cos1 and it's non sine1(cos0) as extremes

>>parents to the hybrid inheritances from each to the degrees between

.

Everything is Displacement(great automotive term), total volume of displacement of distanceXforce input

>>is equal in output (parity check each against the other)

>>less the friction taxations of linear force converted to radial>>and back

>>each conversion must tax, like pouring a gallon of milk from container to container

>>no matter how carefully efficient>>less at end

And just as in pulleys, the co$t of preserving the last 10-15% of the efficiency is the most immense

>>as the smallest increments of change, just as seen in cosine when as like polish up towards 0% deflection

.

A pulley set is as like a transmission, even a zRig with 1 leg to input, 2legs to machine pivot, 3legs to output

>>for more power at less distance potentials as power increase is just un-requitted distance/unachieved

>>so distance and force are reciprocals traded

>>noting the distance in/out is at full calc potential

>>but only the increased(or decreased)force portion taxed to less than full potential

Then can rotate the system functions to the 1-2-3 leg choices to make the 2x as input

>>3x as pivot and 1x as output >> would be half as strong a pull

>>but pull 2x as far(like short drive way run with truck to pull up longer hill)

>>WARNING: this also means covering 2x as much distance as input for DOUBLED SPEED

Voila, Transmission ! >> can have a Super Granny or a weak Hot Rod !

The 1,2,3 lever class of the mechanic is determined by input/output relationships of direction and force(link)

Pulleys are jest rolling levers !

.

The compound systems are amazing, but best on adjustable prussic as reach end of run early between the internal systems, before whole system is totally contracted

>> the 2handed things personally try to show (as inverted DdRT mechanic) don't have jam up problem unless another inset system.

in the simplest forms, 1of the 2 effort or its reflection is w/o friction tax

>>and if target direction is down, bodyweight too then can be untaxed by friction..

.

again, Pulleys are jest rolling levers

2 hand input theory translated from flexibles to rigids(link)