You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rigging your truck unstuck

- Thread starter davidwyby

- Start date

- Replies 72

- Views 8K

More options

Who Replied?I haven't. I have a cable puller like the maasdam around here somewhere, but I haven't even seen it in ~20 years. Bought it and never used it. I think it might be missing parts. I should try finding it and see if it's something I can put to use.

theTreeSpyder

TreeHouser

- Joined

- Feb 12, 2016

- Messages

- 693

I try to show zRig as 3position transmission swapping power for velocity.

It has 1x,2x,3x powers that can be rotated to be used as input, output and machine pivot functions.

Usually input on 1x part, pivot on 2x , output 3x.

Can run backwards as stated and keep 2x as machine pivot but 3x as input, 1x output.

>>3x as fast at 1/3 force.

Could anchor 3xLeg as pivot and input to 2x, for 2x speed at half force to 1x part.

.

Have also used for short run for longer pull of load.

Follow math can put 1x as pivot input 3x , output 2x for 1.5x force increase etc. transmission.

.

It has 1x,2x,3x powers that can be rotated to be used as input, output and machine pivot functions.

Usually input on 1x part, pivot on 2x , output 3x.

Can run backwards as stated and keep 2x as machine pivot but 3x as input, 1x output.

>>3x as fast at 1/3 force.

Could anchor 3xLeg as pivot and input to 2x, for 2x speed at half force to 1x part.

.

Have also used for short run for longer pull of load.

Follow math can put 1x as pivot input 3x , output 2x for 1.5x force increase etc. transmission.

.

Mick!

TreeHouser

I keep hoping to use it to really impress the apprentice!I did it cutting a big pine by my house.

it’s really a useful trick if you’re working alone, which I almost never am.

Actually it’s not a trick, that doesn’t do it justice, it’s a solution using applied mechanics.

Last edited:

theTreeSpyder

TreeHouser

- Joined

- Feb 12, 2016

- Messages

- 693

Not a trick, 'a point(s) of scaled balance'; a triad of input/output/machine pivot.

Picture at full potential, w/o friction, could use as scale of unknown weight to known.

>>just like was fixed overhead pulley, 1:1 legs evenly pulled then to balance

>>anchor 1 leg and now make pulley position adjustable and if can pull down with 10#, top resistance is 20# etc.(hair less actually)

Points of balance of triad, no cheating/all accounted for; not > not < but, VERY uniquely and cross verifiably = ; is our gameboard.

.

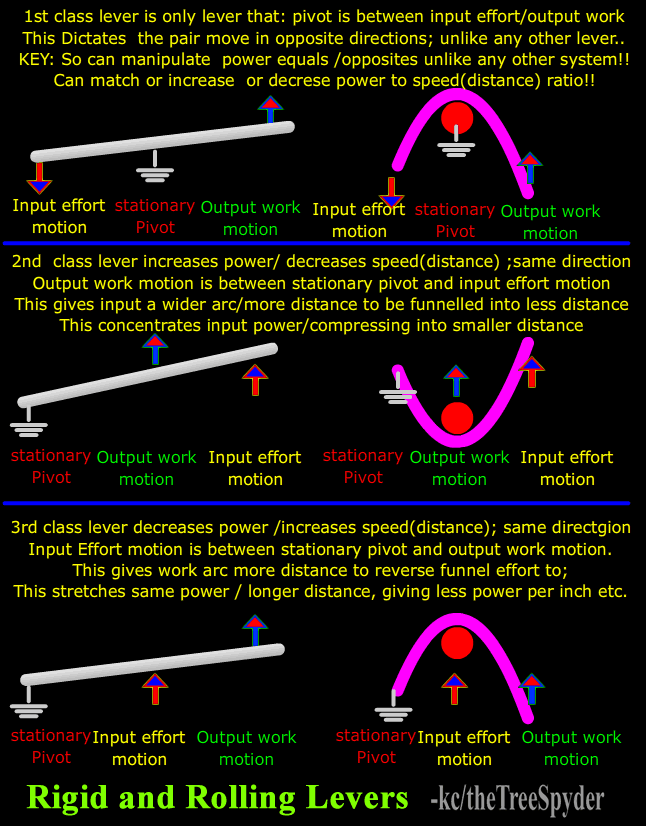

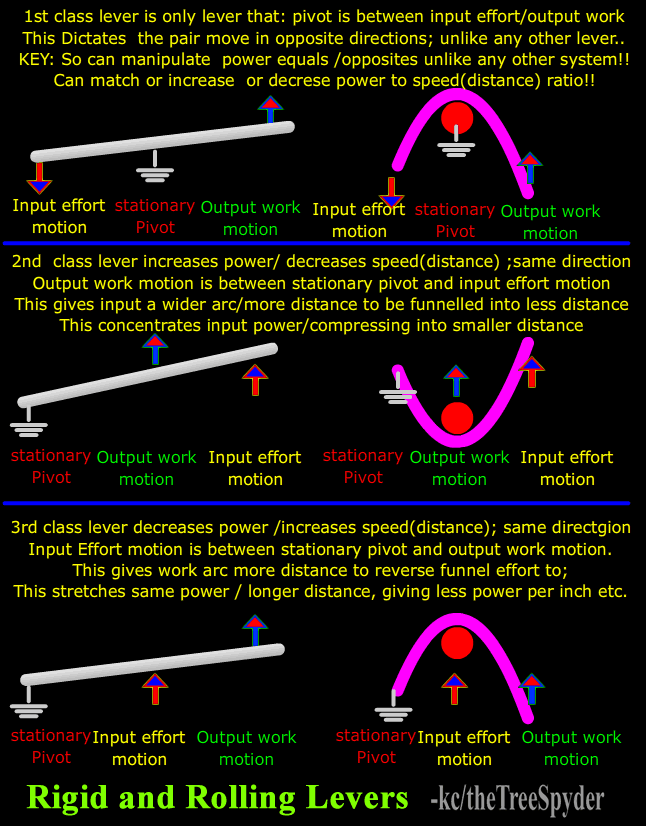

Rolling levers;

Class_1: If input/output in opposite directions, machine pivot must be between

Class_2: Input/output in same directions, machine pivot on 1 end, closest to load, concentrating force density into smaller distance(2:1 etc.)

Class_3: Input/output in same directions, machine pivot on 1 end, closest to input, diluting force density over longer distance (1:2 etc.)

note how written also defines more familiar rigid lever classes of same input/output/machine pivot triad relationships.

Translating these to same 'electrical schematic' of cross comparison allowed to share lessons between both bodies of experience to the other, and even cross verify so etc., in one to verify in the other, to give more weight to both as larger body of knowledge and dimension(not just single dimension of vertical, unverified pile in 1 only).

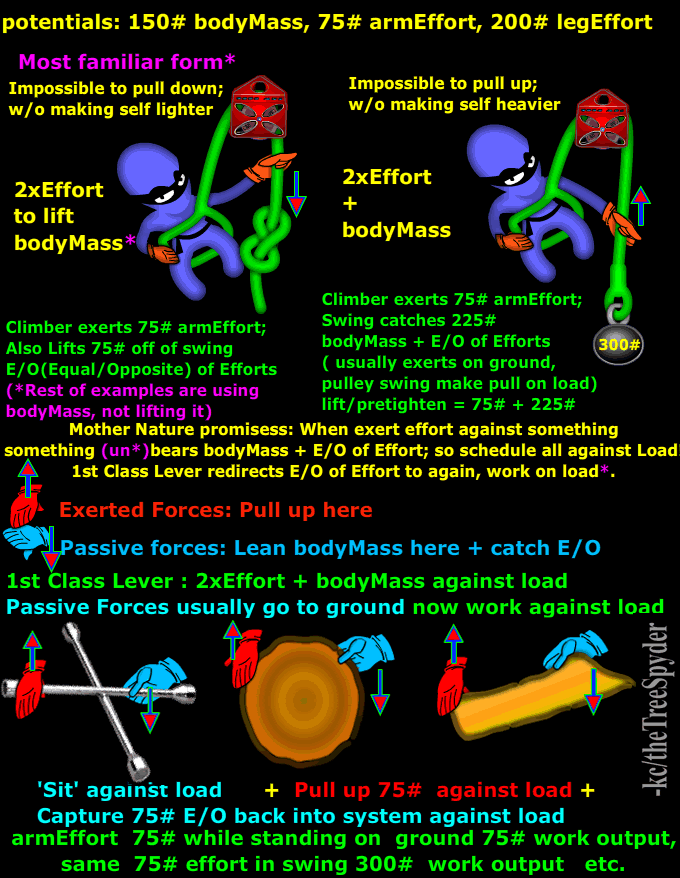

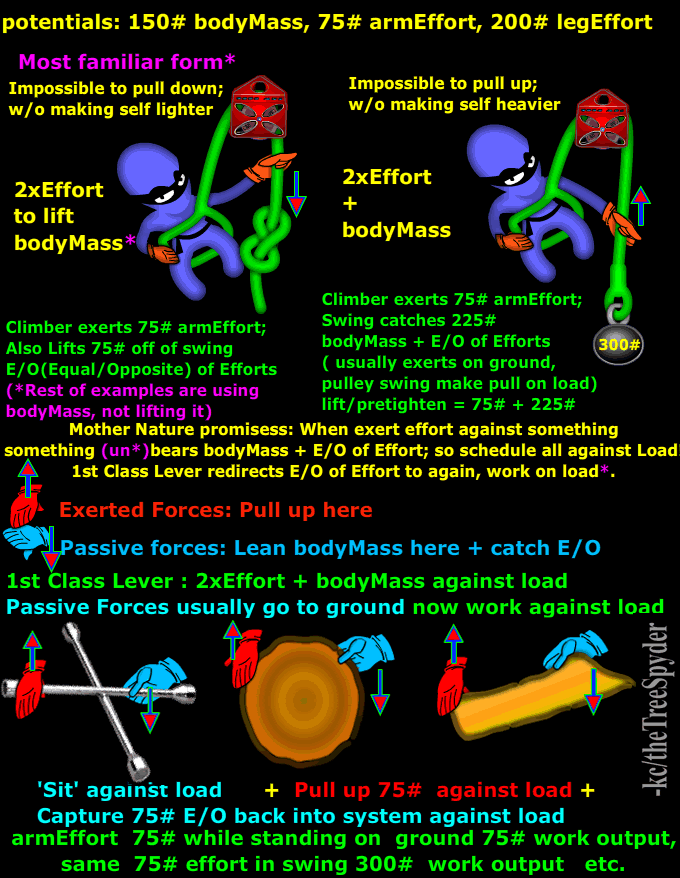

Confidently enough to take 2/1 over own self of DdRT/dumbwaiter lessons, reverse to load lifting/line pre-tightening with bodyweight + 2/1 effort

>>then translate for immediate usage and exploration from flexible to then rigid frameworks:

(my late buddy would call these 'exactly the same, but different')

always visualizing the pivot as between the input outputs of opposing directions.

If lean all weight on r.hand blue glove, and pull up on l.hand red glove

>>blue glove force autonomously increases from bodyweight to bodyweight + red glove effort

Mid pivot is class_1, use it to capture input effort + equal but opposite direction of effort

>>to now fold that quantity back against target/not let run away.

If stand on scale and way 100#, pull up on red glove, makes you heavier on scale

>>unless short circuit force flow to blue glove instead

>>if pick up on red, while holding at blue, and still weigh same on scale, have 2/1

>>if scale drops to 50#, have 2/1 + 50 (i think of this as a martial arts framework of efficiency taking standard theories and invert against their own selves to show counter intuitively theory continues even around that curve, and even stronger as they do w/Chinese Windlass wonder)

>>just as if scale goes to Zer0 on scale then 2/1 + 100# bodyweight.

1 part of system can hold load at bay, as other impacts(bodyweight or effort input quantity), or both can impact, or 1 can impact to initiate movement and other input part as follow thru

>>the 2part input system itself, offers things single/mono input system simply can't simply !

In all things status of Zer0, mono or multi matters.

.

Everything displaces against it's non, here this is distance(thus velocity) for power over same unit of time.

>>distance is free travel expressed

>>force is opposite of free travel restricted.

Total static power volume is Force x Distance, to same total sum as fixed input

>>so FxD are reciprocals of each other to the same sum

>>can increase 1 only at the cost of the other >> to the same total finite input sum

But, every conversion has a tax against the whole input sum

>>with rope friction on arc, this tax is exponentially compounding(capstan theory)

>>soon outrunning to seizing against any compounding of force compressed to denser inside of smaller, tighter distance/container.

Smaller, denser volume packed inside reduced distance container just as if putting same tension volume into smaller diameter footprint rope, to cut into skin harder when carrying; or as friction hitch to grab host harder; is all the same, i swear.

Mes Amigos, i only keep saying as this is how all stuff works; and treewerk one way that shows most cleanly, rawly, at such magnification to view and even feel. Once firmly sift out to see the same illusive 'ghost' form, as goes from setup to setup as most pivotal player; can say 'i see you now'; and know to look for /sift you out from everywhere. In electronics, that is a schematic form, no matter how skinned over. Like for automotive to make a Cougar from Tbird, racers call the body skin. Switch skin is same frame, motor, trans etc. Same functional schematic skinned over differently, just as above rope, lever mechanics. MUCH, much, much less to know to command all more fully, once align to finding the pivotal few real working principles in scenario, and all lessons cross verify each other to greater as go; giving both greater depth and dimension, i still invite.

.

is ok, can come out; crazy midget rant over (fer now.. )

Picture at full potential, w/o friction, could use as scale of unknown weight to known.

>>just like was fixed overhead pulley, 1:1 legs evenly pulled then to balance

>>anchor 1 leg and now make pulley position adjustable and if can pull down with 10#, top resistance is 20# etc.(hair less actually)

Points of balance of triad, no cheating/all accounted for; not > not < but, VERY uniquely and cross verifiably = ; is our gameboard.

.

Rolling levers;

Class_1: If input/output in opposite directions, machine pivot must be between

Class_2: Input/output in same directions, machine pivot on 1 end, closest to load, concentrating force density into smaller distance(2:1 etc.)

Class_3: Input/output in same directions, machine pivot on 1 end, closest to input, diluting force density over longer distance (1:2 etc.)

note how written also defines more familiar rigid lever classes of same input/output/machine pivot triad relationships.

Translating these to same 'electrical schematic' of cross comparison allowed to share lessons between both bodies of experience to the other, and even cross verify so etc., in one to verify in the other, to give more weight to both as larger body of knowledge and dimension(not just single dimension of vertical, unverified pile in 1 only).

Confidently enough to take 2/1 over own self of DdRT/dumbwaiter lessons, reverse to load lifting/line pre-tightening with bodyweight + 2/1 effort

>>then translate for immediate usage and exploration from flexible to then rigid frameworks:

(my late buddy would call these 'exactly the same, but different')

always visualizing the pivot as between the input outputs of opposing directions.

If lean all weight on r.hand blue glove, and pull up on l.hand red glove

>>blue glove force autonomously increases from bodyweight to bodyweight + red glove effort

Mid pivot is class_1, use it to capture input effort + equal but opposite direction of effort

>>to now fold that quantity back against target/not let run away.

If stand on scale and way 100#, pull up on red glove, makes you heavier on scale

>>unless short circuit force flow to blue glove instead

>>if pick up on red, while holding at blue, and still weigh same on scale, have 2/1

>>if scale drops to 50#, have 2/1 + 50 (i think of this as a martial arts framework of efficiency taking standard theories and invert against their own selves to show counter intuitively theory continues even around that curve, and even stronger as they do w/Chinese Windlass wonder)

>>just as if scale goes to Zer0 on scale then 2/1 + 100# bodyweight.

1 part of system can hold load at bay, as other impacts(bodyweight or effort input quantity), or both can impact, or 1 can impact to initiate movement and other input part as follow thru

>>the 2part input system itself, offers things single/mono input system simply can't simply !

In all things status of Zer0, mono or multi matters.

.

Everything displaces against it's non, here this is distance(thus velocity) for power over same unit of time.

>>distance is free travel expressed

>>force is opposite of free travel restricted.

Total static power volume is Force x Distance, to same total sum as fixed input

>>so FxD are reciprocals of each other to the same sum

>>can increase 1 only at the cost of the other >> to the same total finite input sum

But, every conversion has a tax against the whole input sum

>>with rope friction on arc, this tax is exponentially compounding(capstan theory)

>>soon outrunning to seizing against any compounding of force compressed to denser inside of smaller, tighter distance/container.

Smaller, denser volume packed inside reduced distance container just as if putting same tension volume into smaller diameter footprint rope, to cut into skin harder when carrying; or as friction hitch to grab host harder; is all the same, i swear.

Mes Amigos, i only keep saying as this is how all stuff works; and treewerk one way that shows most cleanly, rawly, at such magnification to view and even feel. Once firmly sift out to see the same illusive 'ghost' form, as goes from setup to setup as most pivotal player; can say 'i see you now'; and know to look for /sift you out from everywhere. In electronics, that is a schematic form, no matter how skinned over. Like for automotive to make a Cougar from Tbird, racers call the body skin. Switch skin is same frame, motor, trans etc. Same functional schematic skinned over differently, just as above rope, lever mechanics. MUCH, much, much less to know to command all more fully, once align to finding the pivotal few real working principles in scenario, and all lessons cross verify each other to greater as go; giving both greater depth and dimension, i still invite.

.

is ok, can come out; crazy midget rant over (fer now.. )

Last edited:

Nutball

TreeHouser

I find it best to tension the line first before adding the log, so tension is increased after you apply what you can by hand. Probably would need a micro pulley to pull the log up as high as it should go. I would have a carabiner mid line anyway as part of a mechanical advantage.I keep hoping to use it to really impress the apprentice!

it’s really a useful trick if you’re working alone, which I almost never am.

Actually it’s not a trick, that doesn’t do it justice, it’s a solution using applied mechanics.

Mick!

TreeHouser

I have only envisaged doing it with a loader.

Working solo.

Tie the log halfway, reverse the loader so the log was way in the air, that way the tree is fully committed before the log hits the deck and you lose pull.

But I’ve never done it so ….

Working solo.

Tie the log halfway, reverse the loader so the log was way in the air, that way the tree is fully committed before the log hits the deck and you lose pull.

But I’ve never done it so ….

Last edited:

I never thought about that, but come to think of it, I had around 6K pounds on this maple last week and could still pull the middle of my ~60ft span of rope about 3ft by hand, so a couple hundred pound log will pull it down even more for the same tensionthe log hanging makes the tension seem less than it is.

normally I pull a line till all the slack is gone then back another few feet depending on rope length and what im pulling, but with a log hanging now you got to judge the deflection in the line, may be 10 feet or more pretty easily!

thanks for the reminder that theres more to it than meets the eye

Nutball

TreeHouser

I've let the mini skid drive itself when I'm by myself if pulling down hill, so the machine rolls down hill. It never creeps very fast, but will pull for me.If only envisaged doing it with a loader.

Working solo.

Tie the log halfway, reverse the loader so the log was way in the air, that way the tree is fully committed before the log hits the deck and you lose pull.

But I’ve never done it so ….

SeanKroll

Treehouser

It is useful anytime your Pull will lose tension too early due to the puller being too slow or out of room, solo or team. Side-lean is sometimes a case where you want more momentum.I keep hoping to use it to really impress the apprentice!

it’s really a useful trick if you’re working alone, which I almost never am.

Actually it’s not a trick, that doesn’t do it justice, it’s a solution using applied mechanics.

Like many tricks, rarely is it needed. I've done it, twice.

Any added weight will add tension, and won't prevent any normal pulling force from the machine. Half hitches won't reduce rope strength much. Also possible to hitch a sling to your pull rope, if rope strength is an issue.

(Side note, people get in the habit of choking a stem and running one leg to the machine. With a suitable crotch, basket- ing and running two legs to the machine more than doubles the capacity, as you don't lose strength with a running bowline. Rare is the use of a tensionless hitch at the tree.)

If you're solo, and your machine bleeds off (is there a better term?) at the tracks/wheels, chock the machine if you need time to re-ascend and cut.

Last edited:

SeanKroll

Treehouser

How?I've let the mini skid drive itself when I'm by myself if pulling down hill, so the machine rolls down hill. It never creeps very fast, but will pull for me.

Nutball

TreeHouser

It creeps down hill if the parking brake is not engaged.

Burnham

Woods walker

Oopsie.

CurSedVoyce

California Hillbilly

NOT how you grease your zircs!

gf beranek

Old Schooler

Talk about stuck.

Burnham

Woods walker

Truly stuck. That small excavator was playing with fire, operating in that gloop.

gf beranek

Old Schooler

I was thinking the same thing. Any second now... oops

I think there was some good luck involved.

I think there was some good luck involved.

gf beranek

Old Schooler

Looks like it happens a lot.

The close access and better rigging angles make this recovery a lot easier.

They done this before.

The close access and better rigging angles make this recovery a lot easier.

They done this before.

Terrain can be fickle. Many moons ago I made a small dirt bike trail around my parents property, including rounding the edge of a dried out moat/dugout feature (drought year). All was fine, ground solid till I moved over 12" inadvertently towards where the water would have been. Broke the crust and sunk in the slimy goop to the cases. Realized the folly of my ways and stayed clear of potential crust/goop! In the video looks like about 20' between goop and solid.

Similar threads

- Replies

- 0

- Views

- 830

- Replies

- 29

- Views

- 4K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)