My (witnessed/self taught)take on lever trading between power and speed(distance) from the same finite volume of force:

In rigid levers, if the static pivot is between the dynamic/moving input and output parts/positions, is class_1;

only class_1 levers can reverse directions of input to output and also input/outputs work @same speed(output position_1 of 3 in imagery) where moving input/output are not next to each other, as static pivot is between.

.

When static pivot is on an end/not between input/output can take on other 2 forms/classes:

If the output/load is closest to static pivot , so the farther from pivot input concentrates into the now slower output is class_2, increasing power at co$t of distance/speed(output position_2 of 3 imagery) of inner arc.

.

Input closest to static pivot dilutes power to greater distance/speed in trade to outer arc as output(output position_3 of 3 imagery) as class_3.

.

Any conversion having a friction cost, that asserts against power, for speed/distance trades are rawly maintained. So difference in efficiency varies power input/output ratio , but distance and so speed input/output ratio ratio remains fixed when only efficiency adjusted, as weighs only against power ratio reduction.

Will find rolling/flexible levers the same.

If static pivot is pulley position, between input/outputs, is class_1 redirect only, same speed ,power reduced by friction.

If pulley moves as output between static pivot and input increase power is class_2 at cost to distance/speed in trade.

If pulley moves as input between static pivot and output increase speed is class_3 at cost to power in traded factors to still have same product/force volume(in lossless/costless system).

.

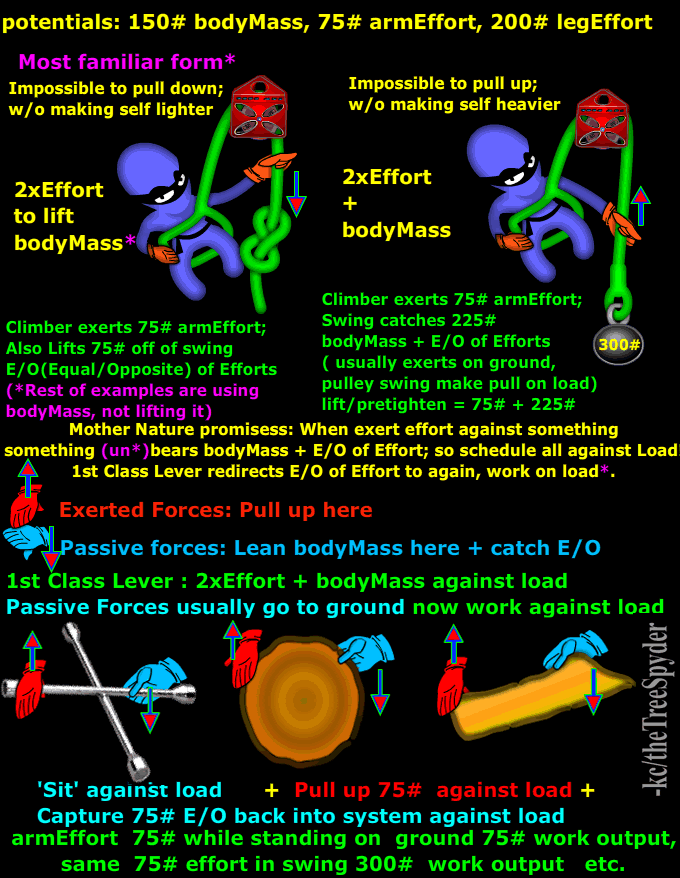

These are for OPEN systems, things change some when CLOSE the system as in:

where equal and opposite of effort is expressed inside the works CLOSED, not outside to (or away from) the ground etc. in the much more common scenarios shown earlier, rather than this purposeful option.

.

This is as like watts as total volume of volts/power and amps/speed manipulations within same quantity, at cost of resistance (as like electrical friction) in force is force view. Or bottle jack narrow input piston convert to wide output piston of less motion distance output but of more power. A finite volume of force into machine to manipulate distance x power factors to same sum product volume. We choose to try to capitalize on force at co$t of distance or vice/versa from same input volume force, just as car transmission from same narrow power band of efficient car motor output etc.

Back to rigid devices, but as falling or otherwise disconnected /in air can see rules still fit from this view:

. Class_1 Pivot is most loaded point then to this view. So if stick is in air and hit an end CoG is most loaded point, as pivot I think. Unless input force lines up to CoG, then is just simple push or pull inline to CoG, not rotational to.