bstewert

TreeHouser

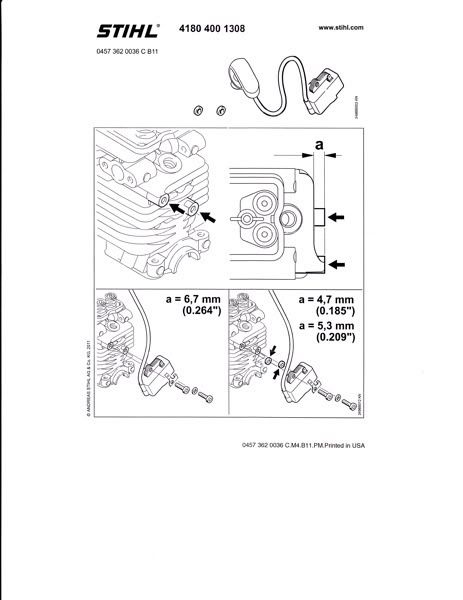

I bought this string trimmer new in '03. It gets used about 20 hrs a year, all in the summer months, and I last used it 3 weeks ago. It's always been tougher to start than my other Stihl tools, but now it's totally dead.

So I did the usual simple tune-up stuff, new filters, plug and fuel. I took the old Bosch plug in (USR 7AC). They gave me a NGK CMR 6H and told me to set the gap at .025. It was still tough to start but it did fire up once after a lot of effort. I said great, and put it up for a few days.

Today, nothing. I don't think I'm getting spark. No cough, spurt or nothing. I found the manual, which says NGK CMR 5H at .028 gap. Stores are closed right now, but is that enough to make a difference? The repair shops are all 4 weeks out this time of year. Thanks in advance for any help.

So I did the usual simple tune-up stuff, new filters, plug and fuel. I took the old Bosch plug in (USR 7AC). They gave me a NGK CMR 6H and told me to set the gap at .025. It was still tough to start but it did fire up once after a lot of effort. I said great, and put it up for a few days.

Today, nothing. I don't think I'm getting spark. No cough, spurt or nothing. I found the manual, which says NGK CMR 5H at .028 gap. Stores are closed right now, but is that enough to make a difference? The repair shops are all 4 weeks out this time of year. Thanks in advance for any help.