lumberjack

Young man on the go

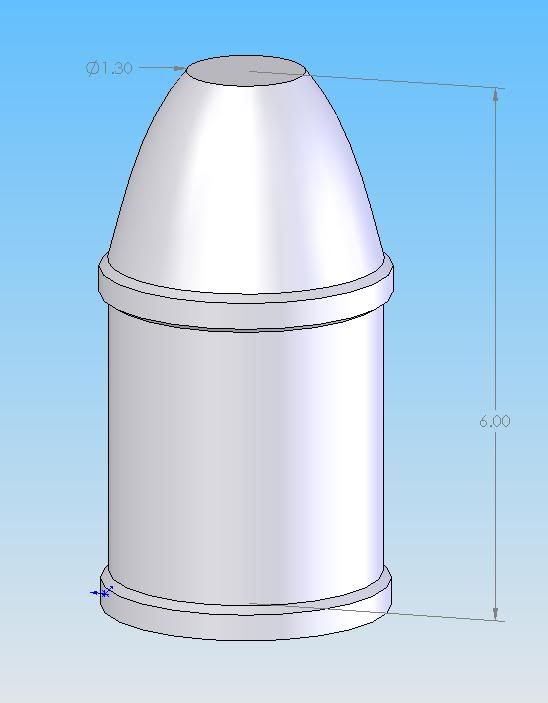

I've gotta design a bullet mold and accessories for a "customer", then turn around and make it.

The stock is a roll journal that he supplied. The plan is to cut a piece to the correct length, cut it in half (like a hotdog) face the mating surfaces and install a couple of locating dowels.

Then put it together and the external profile back in circularity and cylindricity.

Then machine a recessed flat on each half 90* (external) from the mating surface to locate the C clamp while casting. Then put it in the CNC lathe and cut the internal revolved pattern (bullet mold).

Take it back apart and spot face/counter bore one half and put a threaded hole in the same location on the other half to give provisions for pressing the two halves apart by turning in the screws and machine a recess around the edge of the mating surface to protect the mating surface's edge if it's dropped,

There's some other misc features to be added, but that gives you an idea of that part of the project. The base of the mold will be a copy of the existing mold's base for interchangability, there is no sprue cutter.

I also have to design and make a mandrel for his gas checks to fit the new bullet, no biggy there, but more design time.

My question is what is customary to charge for design time? I'd like to give him a bid rather than an hourly rate.

As far as I figure, the only part that will definatly be cnc'ed is the internal pattern.

The stock is a roll journal that he supplied. The plan is to cut a piece to the correct length, cut it in half (like a hotdog) face the mating surfaces and install a couple of locating dowels.

Then put it together and the external profile back in circularity and cylindricity.

Then machine a recessed flat on each half 90* (external) from the mating surface to locate the C clamp while casting. Then put it in the CNC lathe and cut the internal revolved pattern (bullet mold).

Take it back apart and spot face/counter bore one half and put a threaded hole in the same location on the other half to give provisions for pressing the two halves apart by turning in the screws and machine a recess around the edge of the mating surface to protect the mating surface's edge if it's dropped,

There's some other misc features to be added, but that gives you an idea of that part of the project. The base of the mold will be a copy of the existing mold's base for interchangability, there is no sprue cutter.

I also have to design and make a mandrel for his gas checks to fit the new bullet, no biggy there, but more design time.

My question is what is customary to charge for design time? I'd like to give him a bid rather than an hourly rate.

As far as I figure, the only part that will definatly be cnc'ed is the internal pattern.