sawinredneck

Treehouser

No, it's VERY flexible, one of it's most prized traits.

...or your belt buckle

...or your belt buckle

"Run it slow and feed it hard" is the motto for machining titanium.

Magnus thankyou for the history lesson on the chisel chain.Looks like the EM chain... Not so different from Super 70.

First full chisel chains used on saws I think is Disston from mid 40's, a good 20 years before McCulloch..

There are earlier chisel chain patents, but are not sure they sold them much or series produced even.

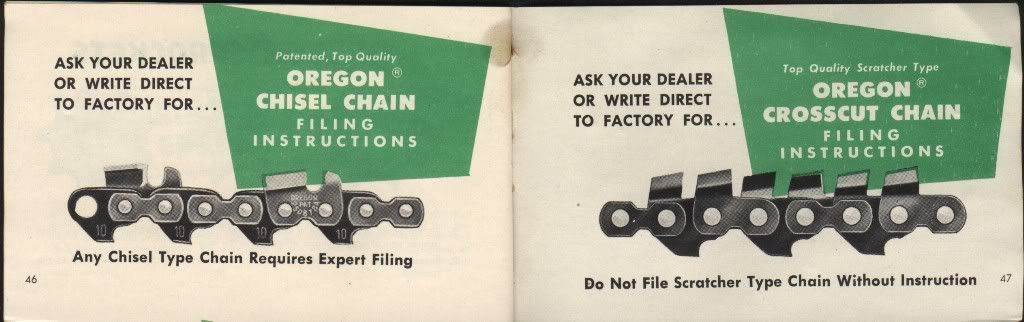

There are older chisel chains than this, but I think this is of the first Oregon chisel chains...Magnus thankyou for the history lesson on the chisel chain.

I always knew Carlton and Oregon intoduced the 3/8" chisel in 1969 [Carlton called theirs "Champion chain"] but I didn't know about Oregon's and the other companies larger 1/2", 9/16", 3/4" chisel from the 1950s. I just found this out from your sawcollectors site yesterday.

Very interesting, thanks again.

Willard.